Resistance To SOPs

These objections are usually emotional responses based on a few reasons.

For one, standardization means across the board, there is a set expectation how to accomplish the task. People resist conforming to standardization because they fear missing the mark and not meeting expectations.

For another, following a procedure means performing work in the required order, adding time to tasks while the employee references each step.

Finally, it takes effort to put something into writing that has heretofore been spoken tradition or that is difficult to capture in a linear step-by-step format.

So, there is a perception that standardized processes are rigid, cumbersome, and overly complex, but this is idealized. Over time, employees internalize the process without need to reference each step. Employees are not robots, and if a change must occur, the SOP does not restrict growth or eliminate adjustments.

The reality is that standardizing your process can speed up your operation, simplify your work, and clarify expectations. The SOP outlines the work and provides guidance for anyone in the role.

Advantages Of SOPs

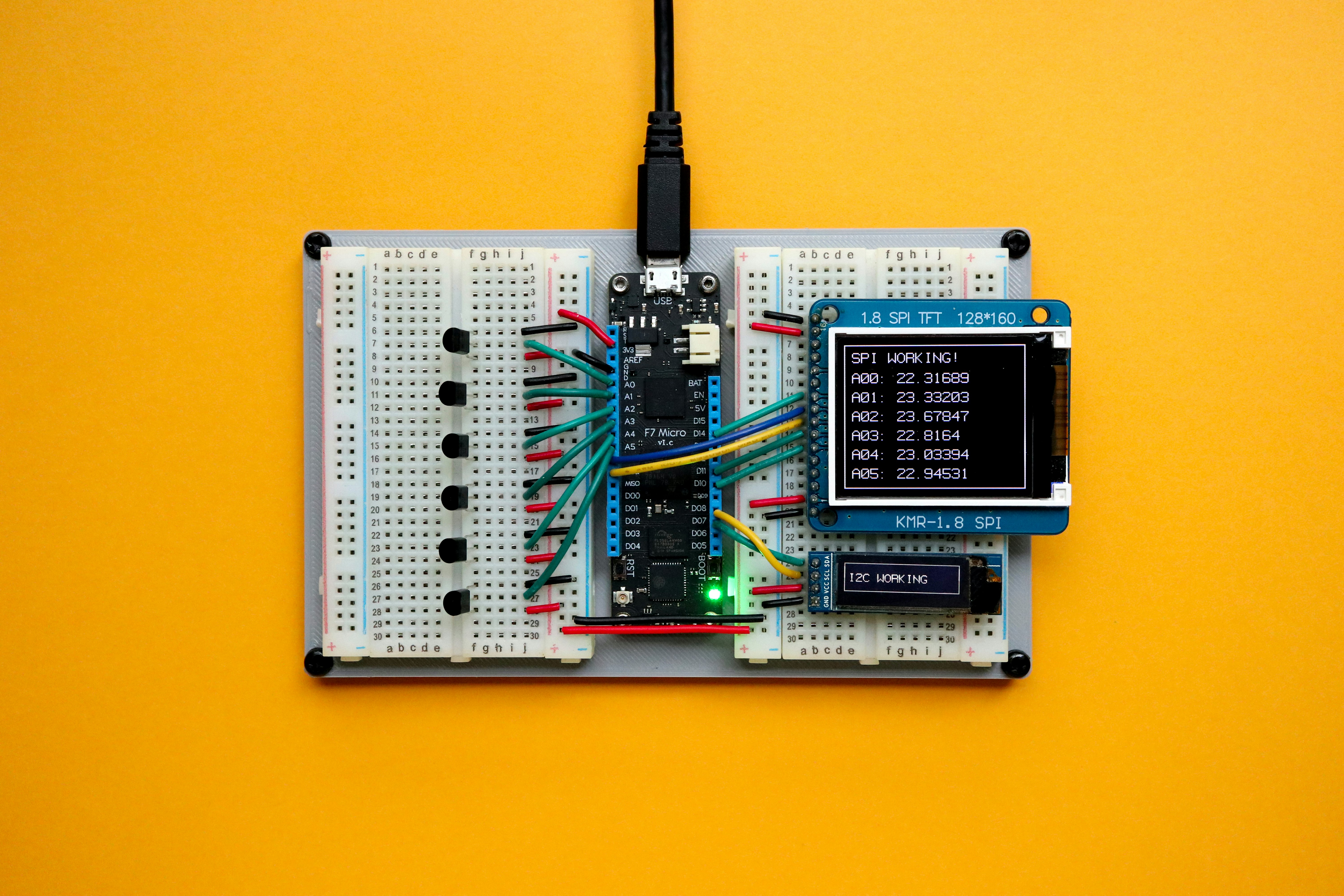

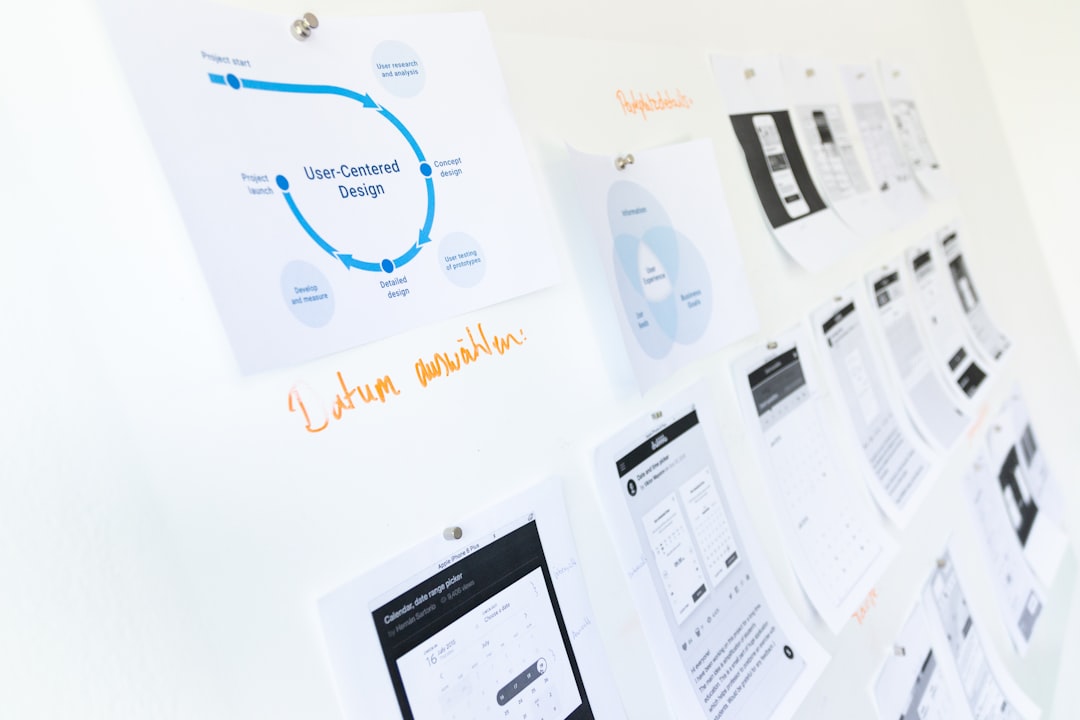

Setting standard work through written instructions that are simple, clear, and visual defines even the most complicated process. If there is an overall understanding or guidance for daily responsibilities, then this could dramatically speed up operations. For example, by defining the process to make a product, a production line can prep the line faster and anticipate needs.

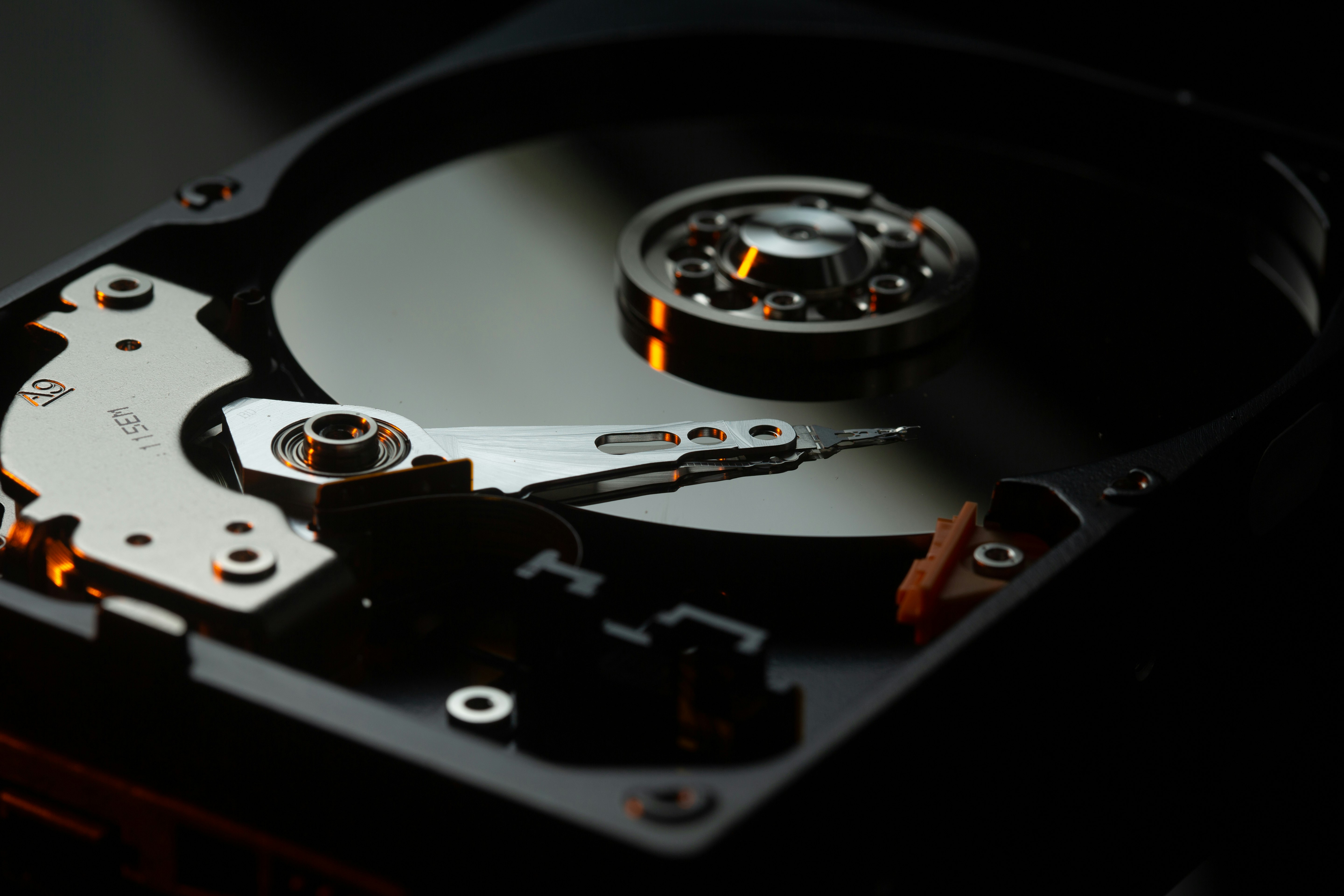

SOPs also preserve the knowledge. Long-term employees who’ve “been there forever” are often keepers of the knowledge, so if they go, the procedure goes with them. If there is advance warning, you can transfer the knowledge, but in some cases like a sudden dismissal, there may not be opportunity. Furthermore, if only one person holds the knowledge, then it’s harder to make business decisions because you may retain the employee for the wrong reason. With an SOP, if the long-term employee leaves and a replacement steps in, the clearly defined process is there as an easy reference to get them up-and-running faster.

Standardizing processes also allows you to address complex processes and determine more precise steps. Often, a process grows out of necessity, routine, or error, as a reactionary band-aid to a problem. There may be redundant reviews or checks that take too much time. When you standardize, you can see just how many steps your current process has or how many times the same person touches a product and identify any inefficiencies.

Make It SOP To Have SOPs

If every employee consciously outlines his or her responsibilities and subsequent tasks, your business has a road map to follow no matter who occupies the role. If creating or using an SOP is just another step in the position description, then it’s easier for a company culture to embrace and follow, limiting resistance.