In the dynamic world of business operations, lean practices have emerged as a transformative approach to optimizing processes and reducing waste. In recent years, various industries have started embracing these principles to enhance efficiency, drive innovation, and achieve sustainable growth.

Businesses striving for excellence are finding that lean methodologies not only streamline their operations but also foster a culture of continuous improvement. This cultural shift is crucial in today's fast-paced business environment where adaptability and responsiveness can determine a company's success.

One shining example of the successful implementation of lean practices is Toyota. This automotive giant revolutionized its production system by focusing on minimizing waste, improving quality, and fostering teamwork. The Toyota Production System has become a gold standard that organizations across various sectors have sought to emulate.

However, the journey towards lean operations isn't without its challenges. It requires a fundamental change in mindset, encouraging employees to embrace change and seek continuous improvements. Furthermore, it underscores the importance of leadership in guiding teams towards this shared vision.

As a seasoned consultant, I've seen companies leverage lean practices to transform their operations effectively. At KPMG, we assisted a major healthcare provider in adopting lean principles to improve patient care and enhance operational efficiency. By streamlining processes, they significantly reduced patient wait times and enhanced overall service quality.

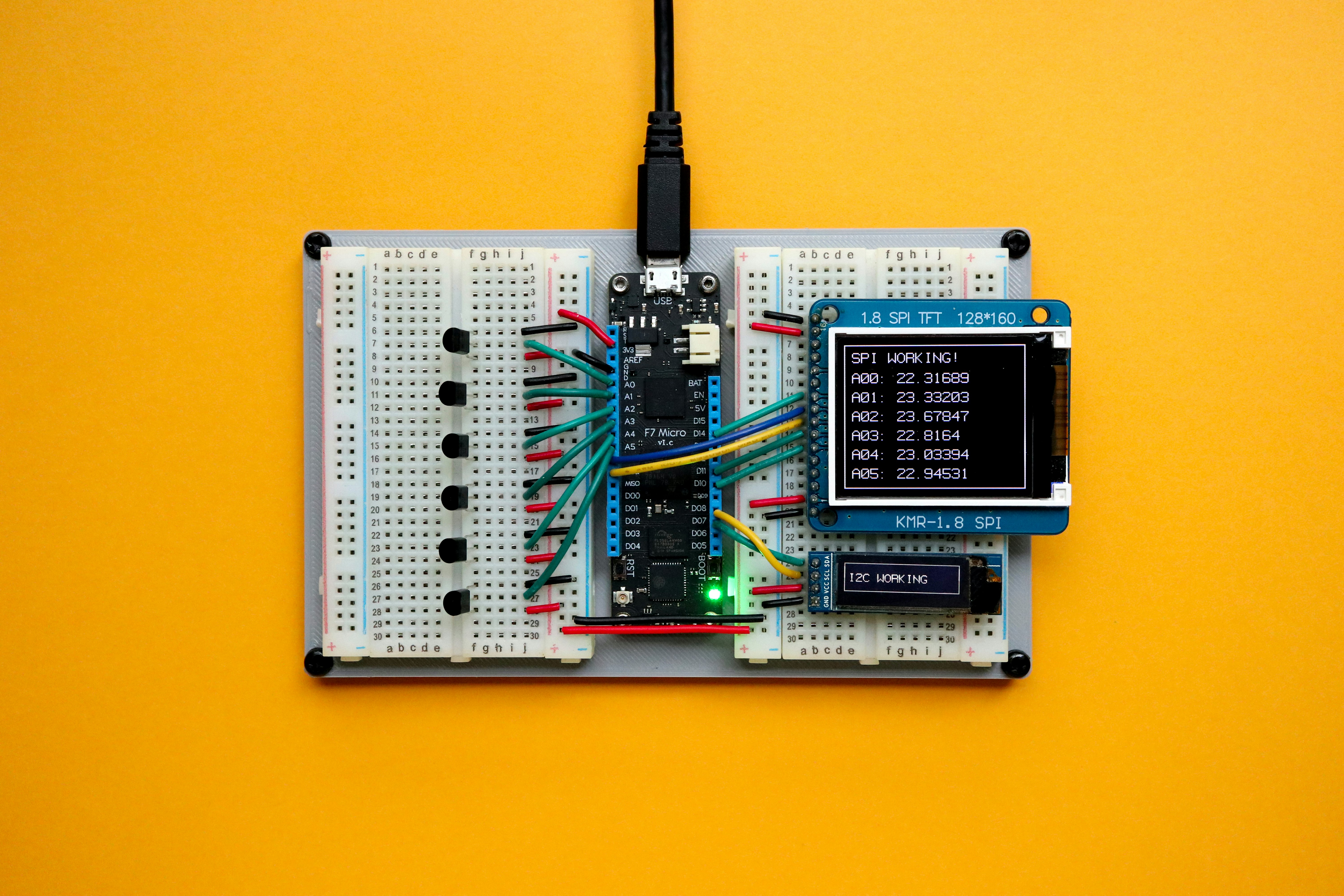

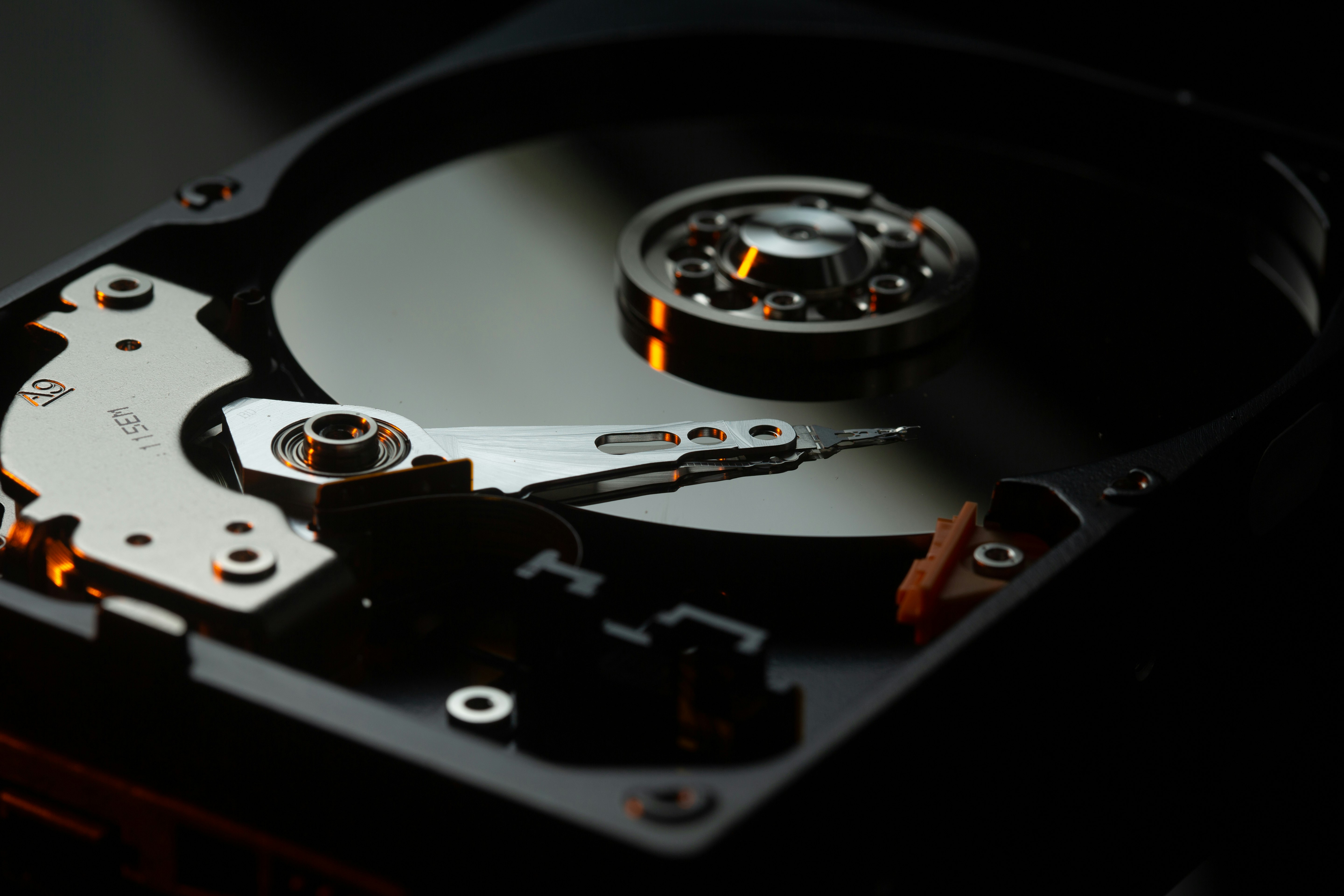

In today's tech-driven age, digital tools play a pivotal role in supporting lean practices. Automation, data analytics, and artificial intelligence are being harnessed to further streamline processes. For instance, predictive analytics can help in demand forecasting, allowing businesses to align their operations with market needs more accurately.

Businesses looking to adopt lean methodologies should start by conducting a thorough assessment of their existing processes. Identifying bottlenecks and areas of waste is crucial in determining where lean interventions can be most effective. Also, fostering a culture of openness to change and willingness to experiment with different solutions can accelerate the transition.

In conclusion, the embrace of lean practices in modern operations is more than just a trend—it's a strategic imperative. By focusing on continuous improvement and eliminating waste, organizations can achieve greater efficiency, agility, and competitiveness in the marketplace.

Estimated reading time: 1 minute, 52 seconds

Embracing Lean Practices in Modern Operations Featured

Explore the transformative impact of lean practices in business operations, drawing insights from Toyota's success and modern tech integration.

Explore the transformative impact of lean practices in business operations, drawing insights from Toyota's success and modern tech integration.

Latest from Successful Business News

- Streamlining Business Operations: Embracing Automation in 2023

- The Rise of Data-Driven Sales Strategies in 2023

- Revolutionizing HR with AI: The Future of Workforce Management

- Embracing Circular Economy: Transforming Operations for Sustainable Growth

- The Role of Operational Agility in Business Success

Most Read

-

-

Feb 08 2012

-

Written by SBN Editors

-

-

-

Sep 08 2011

-

Written by Editor

-

-

-

Jun 18 2013

-

Written by News

-

-

-

Nov 14 2012

-

Written by SBN Editors

-