Navigating supply chain disruptions is becoming increasingly critical for businesses aiming to maintain operational efficiency and continuity. With factors such as geopolitical tensions, natural disasters, and unexpected global events, having a robust strategy in place is no longer optional—it’s essential.

In recent news, several multinational corporations have been struggling with supply chain setbacks. Companies like Toyota and Apple have both publicly addressed challenges stemming from semiconductor shortages and logistic bottlenecks. These disruptions have emphasized the importance of agile supply chain management strategies.

A key technique for overcoming these disruptions is diversifying supplier bases. Companies that rely heavily on single-source suppliers are more vulnerable to these disruptions. As seen in the recent case of the electronics industry, businesses that had diversified partnerships were able to mitigate risks significantly better than their peers. By fostering relationships with multiple suppliers across different geographical regions, companies can balance risk and avoid major hiccups in production and delivery.

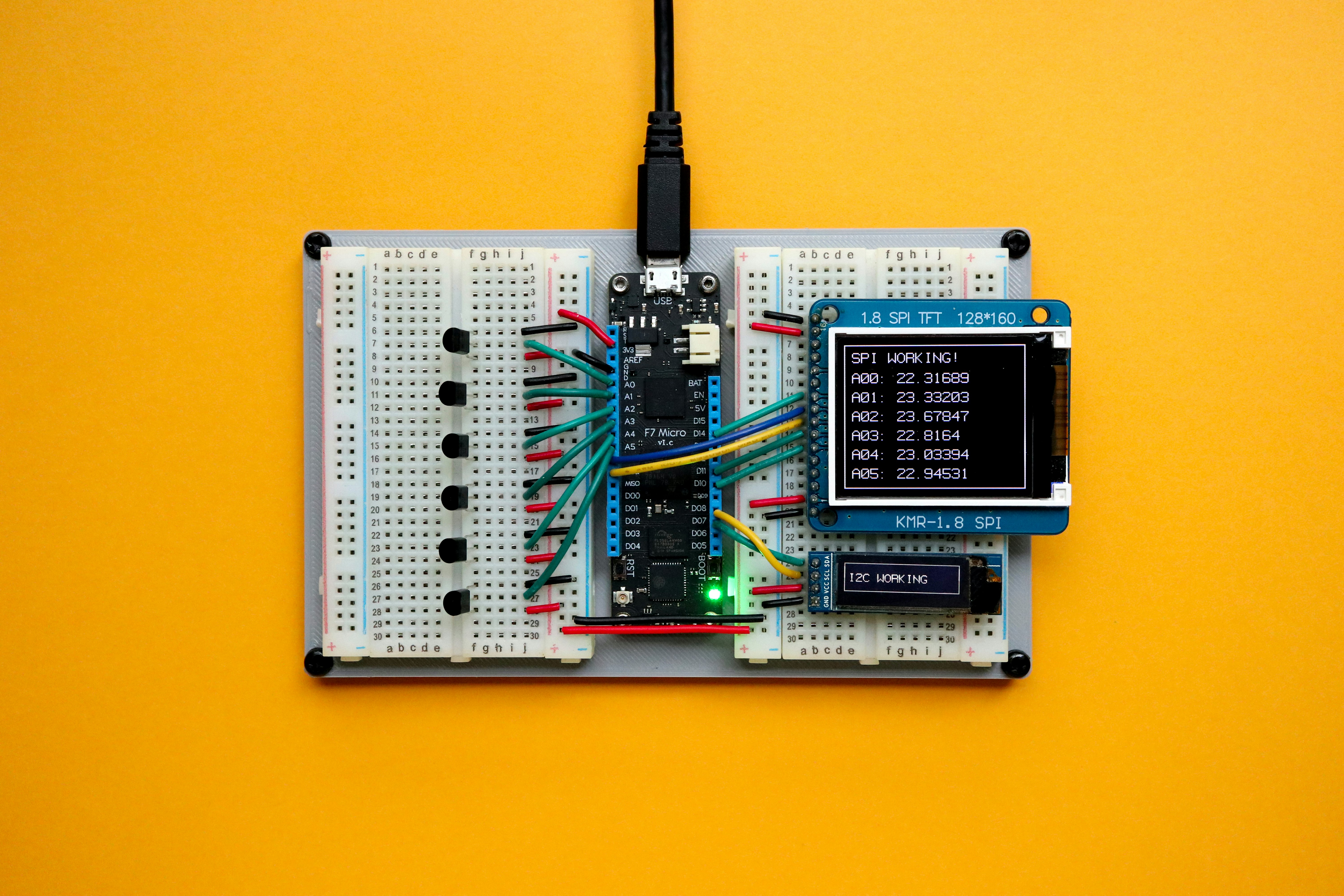

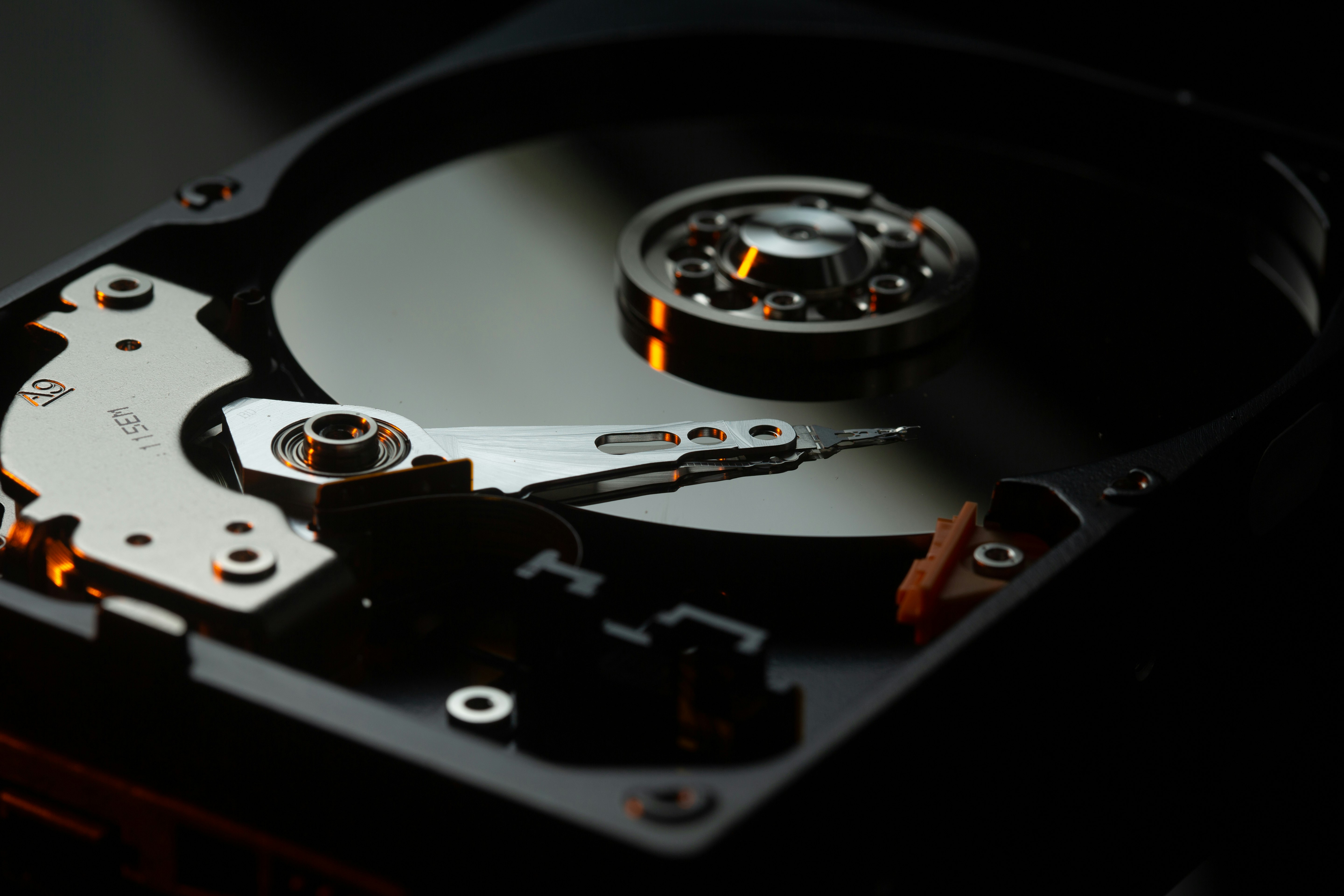

Another critical strategy involves leveraging technology to enhance visibility across the supply chain. With tools such as AI-driven analytics and blockchain technology, businesses can gain real-time insights into their supply chain processes. This increased visibility not only helps in identifying potential bottlenecks but also enables companies to make data-driven decisions swiftly.

Moreover, investing in local production capabilities where feasible can be a game-changer. This is a strategy that many industries started considering seriously following the pandemic's initial supply chain shocks. By keeping certain elements of manufacturing closer to key markets, companies reduce dependency on international logistics, which can be subject to delays and fluctuating costs.

Flexibility is another essential component. Organizations that can quickly pivot and adapt their operational strategies in response to changing conditions are more likely to thrive. Implementing scenarios and contingency planning ensures that businesses have plans in place to deal with a variety of disruption scenarios.

A notable example of successful supply chain management is that of Procter & Gamble (P&G). Their dedicated risk management teams continuously assess potential supply chain risks and develop strategies to mitigate these threats. As a result, P&G has been able to maintain steady product availability even during times of significant global disruption.

To sum up, navigating supply chain disruptions requires a thoughtful approach involving diversification, technological innovation, local investments, and strategic flexibility. As businesses adopt these strategies, they not only reinforce their operations against disruptions but also position themselves for long-term success.

Estimated reading time: 2 minutes, 6 seconds

Navigating Supply Chain Disruptions: A Strategic Approach for Business Continuity Featured

Explore strategic approaches for overcoming supply chain disruptions ensuring business continuity. Learn how diversification, technology, and flexibility can shield against operational hiccups.

Explore strategic approaches for overcoming supply chain disruptions ensuring business continuity. Learn how diversification, technology, and flexibility can shield against operational hiccups.

Latest from Successful Business News

- Streamlining Business Operations: Embracing Automation in 2023

- The Rise of Data-Driven Sales Strategies in 2023

- Revolutionizing HR with AI: The Future of Workforce Management

- Embracing Circular Economy: Transforming Operations for Sustainable Growth

- The Role of Operational Agility in Business Success

Most Read

-

-

Feb 08 2012

-

Written by SBN Editors

-

-

-

Sep 08 2011

-

Written by Editor

-

-

-

Jun 18 2013

-

Written by News

-

-

-

Nov 14 2012

-

Written by SBN Editors

-